Can you guys tell me if this guide train makes any sense to you?

I put an RV6 20" from the reel face. I put a 5KB 8-1/16" from there. I got that spacing from taking the reel off, looking through the RV6, and centering the 5KB in the middle like a target. I tried doing the same with the first size 4 guide, but it ended up being about 2.5" away.

I have a size 4.5 tip top. From there, I put the first 4KT guide 4" away. I did what I believe to be a static load test starting at 5" spacing, but the line dipped below the rod when I did that. I started again at 4" spacing and I was happy with that.

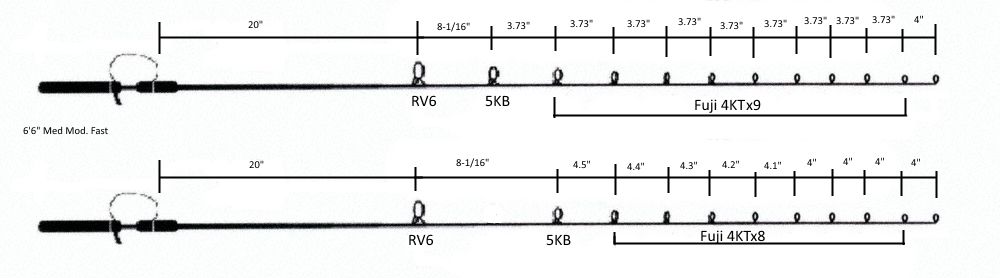

So, with the first guide in place past the tip top and the last two guides in place, I have one Fuji RV6, one Fuji size 5, 9 Fuji size 4, and the tip top. If I space them out evenly, the spacing shrinks from 4" to 3.73" between each guide. I don't know if this helps to illustrate it, but it looks like this.

TT,4 ,4 ,4 ,4 ,4 ,4 ,4 ,4 ,4 ,5 RV6

4",3.73",3.73",3.73",3.73",3.73",3.73",3.73",3.73",3.73",8-1/16",20" from reel

Is that spacing ok, or should I remove a single guide, keep the 4" spacing in the beginning, and move each guide back a little more than 4" to make the spacing more gradual? Something like this.

TT,4 ,4 ,4 ,4 ,4 ,4 ,4 ,4 ,5, RV6

4",4",4",4",4.1",4.2",4.3",4.4",4.5",8-1/16",20" from reel

I put an RV6 20" from the reel face. I put a 5KB 8-1/16" from there. I got that spacing from taking the reel off, looking through the RV6, and centering the 5KB in the middle like a target. I tried doing the same with the first size 4 guide, but it ended up being about 2.5" away.

I have a size 4.5 tip top. From there, I put the first 4KT guide 4" away. I did what I believe to be a static load test starting at 5" spacing, but the line dipped below the rod when I did that. I started again at 4" spacing and I was happy with that.

So, with the first guide in place past the tip top and the last two guides in place, I have one Fuji RV6, one Fuji size 5, 9 Fuji size 4, and the tip top. If I space them out evenly, the spacing shrinks from 4" to 3.73" between each guide. I don't know if this helps to illustrate it, but it looks like this.

TT,4 ,4 ,4 ,4 ,4 ,4 ,4 ,4 ,4 ,5 RV6

4",3.73",3.73",3.73",3.73",3.73",3.73",3.73",3.73",3.73",8-1/16",20" from reel

Is that spacing ok, or should I remove a single guide, keep the 4" spacing in the beginning, and move each guide back a little more than 4" to make the spacing more gradual? Something like this.

TT,4 ,4 ,4 ,4 ,4 ,4 ,4 ,4 ,5, RV6

4",4",4",4",4.1",4.2",4.3",4.4",4.5",8-1/16",20" from reel